Underwater lighting is often perceived as a visual upgrade, yet its true success is determined long before the lights are switched on. While fixtures receive most of the attention, the components that support them quietly decide performance, safety, and lifespan. In underwater environments, even a minor technical oversight can lead to system failure, electrical risks, or costly rework. Therefore, accessories are no longer optional add-ons; they are structural elements of the lighting system itself.

In challenging climatic regions with high humidity, seasonal rainfall, and fluctuating water chemistry, installations demand deeper technical planning. As a result, every Underwater Lighting Installation Company in Kolkata places significant emphasis on accessories such as cables, drivers, and controllers during the design and execution phases. These elements ensure that underwater lights function reliably under pressure, temperature variation, and prolonged exposure to water.

Moreover, modern underwater lighting is expected to deliver more than illumination. Energy efficiency, automation, visual precision, and long-term safety are now baseline expectations. These outcomes are shaped by accessories rather than fixtures alone. Consequently, informed decision-making around accessories has become central to middle and bottom funnel user intent, where users are actively seeking dependable, professional-grade solutions.

This comprehensive guide explores underwater lighting accessories in detail, focusing on their technical roles, selection criteria, Indian compliance standards, and real-world applications. Additionally, Underwater Light Accessories are examined from a performance and longevity perspective, ensuring clarity for planners, engineers, and decision-makers involved in underwater lighting projects.

Understanding Underwater Lighting as a Complete System

Underwater lighting should always be approached as an integrated system. Fixtures, accessories, power sources, and control mechanisms work together to deliver consistent results. When any one component underperforms, the entire system is compromised.

Why a System-Based Approach Is Essential

Water is an unforgiving environment for electrical installations. Even small inconsistencies in insulation, voltage regulation, or sealing can escalate into serious issues. Therefore, accessories serve as safeguards that protect fixtures while maintaining performance.

Furthermore, Indian electrical infrastructure often experiences voltage fluctuations and environmental stress. As a result, accessories are designed not only to support lighting but also to stabilize and protect it. This system-based approach reduces downtime, improves safety, and ensures compliance with national standards.

Core Categories of Underwater Lighting Accessories

Underwater lighting systems rely on multiple accessory types that work together to ensure safety, performance, and long-term reliability. Each category serves a distinct operational purpose, making informed selection essential during planning and installation. Working with a professional Underwater Lighting Installation Company in Kolkata ensures that these accessories are chosen and integrated correctly for optimal performance.

1. Power Delivery Components

These accessories are responsible for transmitting electricity safely from the source to underwater fixtures. They include submersible cables, connectors, and junction systems designed to withstand constant water exposure. High-grade insulation, chemical resistance, and mechanical strength are critical, as power delivery failures are one of the most common causes of underwater lighting breakdowns.

2. Power Regulation and Control Components

This category includes drivers, transformers, and controllers that regulate voltage and current. They protect fixtures from power fluctuations, enable dimming or color control, and support automation features such as timers or synchronized lighting effects. Proper regulation improves energy efficiency and extends fixture lifespan.

3. Protection and Safety Components

These accessories safeguard the entire system against water ingress, corrosion, and electrical hazards. Waterproof junction boxes, sealing compounds, earthing systems, and isolation devices fall under this category. Their primary role is to ensure compliance, user safety, and uninterrupted operation in harsh underwater environments.

Underwater Cables: The Backbone of Electrical Reliability

Underwater cables form the foundation of any submerged lighting system. They carry electrical power across environments where exposure to water, chemicals, and pressure is constant.

Why Standard Electrical Cables Are Not Suitable

Conventional electrical cables lack the insulation and durability required for underwater use. When submerged, they deteriorate rapidly, leading to insulation breakdown and leakage currents.

Underwater cables, on the other hand, are engineered with multi-layer protection. These layers prevent water penetration while maintaining flexibility and tensile strength.

Key Technical Features of Underwater Cables

High-performance underwater cables are designed with the following characteristics:

-

Multi-layer insulation systems

-

Resistance to UV radiation and chemicals

-

High mechanical strength

-

Flame-retardant properties

-

Long-term flexibility under pressure

These features ensure consistent power transmission even in demanding environments.

Commonly Used Underwater Cable Types in India

Different applications require different cable constructions.

| Cable Type | Typical Application | Performance Advantage |

|---|---|---|

| Rubber Insulated Flexible Cables | Pools and fountains | High flexibility |

| Flat Submersible Cables | Large water bodies | Stable load handling |

| XLPE Insulated Cables | Long cable runs | Thermal resistance |

Industry observations in India indicate that a significant percentage of underwater lighting failures are linked to cable degradation. Therefore, cable selection is considered one of the most critical decisions in system design.

Installation Best Practices for Underwater Cables

Cables should be routed through protective conduits wherever possible. Sharp bends and stress points should be avoided, as they weaken insulation over time. Additionally, joints must be minimized, since each joint introduces a potential failure point.

In professional installations across eastern India, cable routing is carefully planned during the design phase to avoid post-installation adjustments.

Drivers: Ensuring Stable Power and Extended Fixture Life

Drivers regulate electrical input to underwater lights, particularly LED fixtures. Without proper drivers, LEDs are exposed to voltage fluctuations that shorten their lifespan.

The Role of Drivers in Indian Electrical Conditions

Power supply variations are common across many regions. Drivers stabilize voltage and current, protecting fixtures from sudden surges or drops. As a result, light output remains consistent and energy efficiency improves.

Types of Drivers Used in Underwater Lighting

Driver selection depends on fixture design and system requirements.

Common driver types include:

-

Constant current drivers

-

Constant voltage drivers

-

Dimmable drivers

-

Isolated waterproof drivers

Each type serves a specific function and must be matched correctly with fixtures.

Driver Housing and Placement Considerations

Drivers are generally installed outside the water. They are housed in ventilated, moisture-resistant enclosures. In humid environments, higher ingress protection ratings are preferred to prevent condensation and corrosion.

Controllers: Precision Control and Visual Customization

Controllers determine how underwater lights behave. They enable adjustments in brightness, color, and timing without physical modifications.

Why Controllers Are Increasingly Essential

Modern underwater lighting projects demand flexibility. Controllers allow lighting scenes to be modified for different occasions or operational needs. Consequently, systems remain adaptable over time.

Controller Capabilities That Enhance Performance

Controllers typically offer:

-

Brightness regulation

-

Color sequencing

-

Automated scheduling

-

Synchronization across fixtures

These features reduce manual intervention and improve operational efficiency.

Common Controller Technologies in Use

| Controller Type | Function | Typical Application |

|---|---|---|

| DMX Controllers | Advanced effects | Architectural water features |

| RGB Controllers | Color mixing | Decorative pools |

| Timer Controllers | Automated operation | Public installations |

Automation has been shown to reduce operational inconsistencies while improving energy management.

Junction Boxes and Connectors: Maintaining Electrical Integrity

Junction boxes and connectors serve as critical transition points between cables and fixtures.

Importance of Waterproof Junction Boxes

Waterproof junction boxes prevent moisture ingress and electrical leakage. They also simplify maintenance by allowing access to connections without disturbing fixtures.

Key selection criteria include:

-

High ingress protection ratings

-

Corrosion-resistant materials

-

Adequate internal space for heat dissipation

Connector Quality and System Compatibility

Connectors must match cable specifications precisely. Loose or incompatible connectors often result in intermittent failures, which are difficult to diagnose once systems are submerged.

Sealing and Insulation Components: Hidden Protectors

Sealing materials protect internal wiring from water and chemical exposure.

Commonly Used Sealing Materials

-

Silicone-based sealants

-

Heat-shrink tubing

-

Epoxy resin compounds

These materials are selected based on water type and temperature conditions.

Compliance and Safety Standards in India

Underwater lighting accessories must comply with national electrical and safety standards.

Key Compliance Requirements

-

Low-voltage operation for submerged fixtures

-

Proper earthing systems

-

Isolation transformers

-

Certified insulation materials

Compliance ensures user safety and reduces liability risks.

Application-Specific Accessory Selection

Different water bodies impose different technical demands.

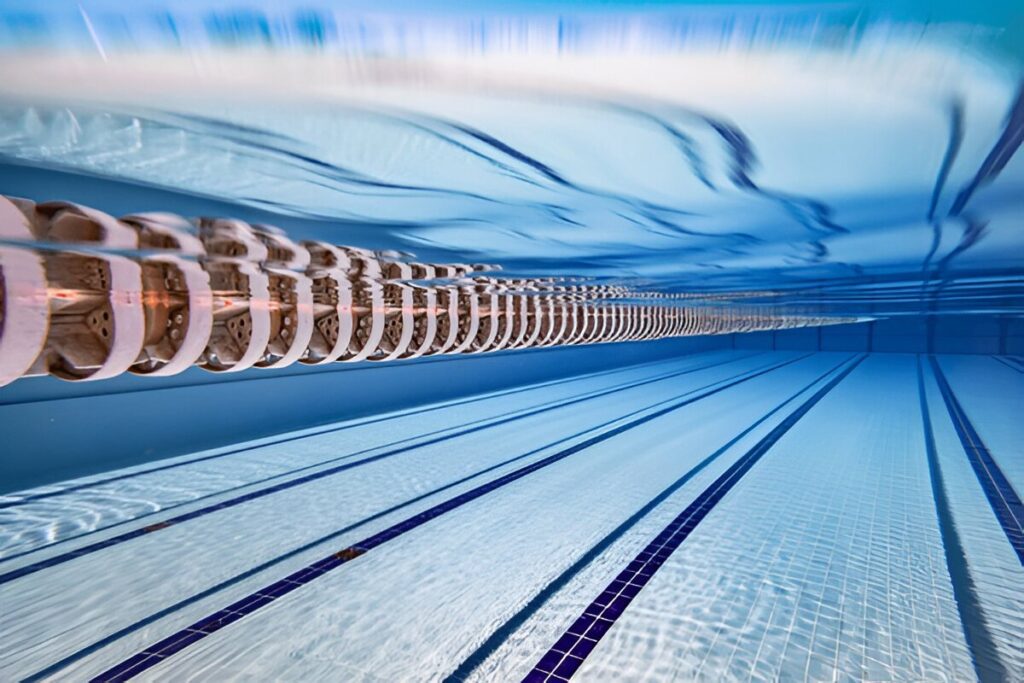

Swimming Pools

Pool installations demand accessories that resist chlorine, salt, and chemical treatments. Cables and connectors must have high chemical tolerance, while sealing materials should withstand frequent cleaning and water replacement cycles. Low-voltage components are preferred to enhance user safety.

Fountains and Decorative Water Features

Continuous water movement and pressure variations require highly flexible cables and vibration-resistant connectors. Accessories must handle dynamic loads and frequent on–off cycles without insulation fatigue or loose connections.

Natural Water Bodies

Lakes and ponds introduce organic matter, sediment, and fluctuating water levels. Therefore, corrosion-resistant materials, reinforced insulation, and robust sealing systems are essential for long-term reliability.

Regional Considerations for Eastern India

Kolkata’s climate presents unique challenges. High humidity, extended monsoon seasons, and temperature variation affect accessory performance.

Therefore, every Underwater Lighting Installation Company in Kolkata emphasizes pre-installation planning. Load calculations, cable routing, and enclosure placement are carefully mapped to address these conditions.

Common regional user concerns include:

-

Reliability during monsoons

-

Long-term insulation performance

-

Maintenance accessibility

These concerns are addressed primarily through accessory selection.

Maintenance and Lifecycle Management of Accessories

Underwater lighting accessories operate in harsh conditions and therefore require structured maintenance to sustain performance, safety, and reliability over time. Without routine checks, minor wear can gradually develop into system-wide failures. A planned maintenance strategy also helps prevent unexpected downtime and costly repairs.

Recommended Maintenance Practices

-

Annual visual inspection of cables

Cable insulation should be checked for cracks, stiffness, or discoloration caused by prolonged water exposure, chemicals, or UV radiation. Early detection prevents electrical leakage and power loss. -

Regular controller and driver checks

Controllers and drivers should be monitored for overheating, irregular output, or communication errors. Firmware and settings must be verified to ensure consistent operation and automation accuracy. -

Resealing and inspection of junction boxes

Junction boxes should be opened periodically to confirm that seals remain intact. Any signs of moisture, corrosion, or loose connections must be addressed immediately.

With proactive maintenance, accessory lifespan is extended, operational risks are reduced, and overall system efficiency is preserved for the long term.

Common Mistakes in Accessory Selection

Accessory-related failures in underwater lighting systems are often caused by design-stage oversights rather than product defects. Limited technical understanding or cost-driven decisions frequently lead to long-term performance issues and safety risks.

Frequent Issues to Avoid

-

Overloading drivers

Selecting drivers without proper load calculations can result in overheating, unstable output, and premature failure. Drivers should always operate within their rated capacity to ensure consistent performance and extended lifespan. -

Ignoring ingress protection (IP) ratings

Accessories without appropriate IP ratings are vulnerable to moisture ingress. This oversight often leads to corrosion, short circuits, and electrical leakage, especially in submerged or high-humidity environments. -

Mixing incompatible components

Using cables, connectors, and drivers that are not electrically or mechanically compatible creates weak points in the system. Mismatched components often cause intermittent faults that are difficult to diagnose.

By avoiding these mistakes and prioritizing compatibility, compliance, and capacity planning, underwater lighting systems achieve greater reliability, safety, and long-term operational stability.

Structured Decision Framework for Accessories

Accessory selection should follow a systematic process.

Step-by-Step Selection Approach

-

Assess environmental conditions

-

Define electrical load requirements

-

Select certified components

-

Plan routing and enclosures

-

Schedule inspections

This approach ensures consistency and safety.

How Accessories Influence Energy Efficiency

Efficient accessories play a crucial role in reducing energy consumption in underwater lighting systems. Properly matched drivers minimize power loss, while advanced controllers optimize output through precise regulation and automation. Together, they ensure consistent illumination, lower energy waste, and long-term efficiency without compromising lighting performance or visual quality.

The Importance of Professional Expertise

Successful underwater lighting installations rely heavily on professional expertise, especially when integrating critical components such as cables, drivers, and controllers. Even high-quality fixtures can underperform if accessories are selected or installed incorrectly. Professional planning ensures that every component functions optimally within the system, minimizing risks and extending service life.

Key Reasons to Rely on Professional Expertise:

-

Accurate System Design – Professionals assess water type, depth, electrical load, and environmental factors to choose compatible Underwater Light Accessories.

-

Compliance with Standards – Expert installers ensure adherence to Indian safety and electrical regulations, reducing risks of electrical hazards.

-

Proper Installation of Accessories – From routing submersible cables to placing drivers and controllers in optimal locations, professionals ensure long-term reliability.

-

Regional Knowledge – Companies in Kolkata understand local climate challenges, such as high humidity and monsoon rainfall, which influence accessory performance.

-

Efficient Maintenance Planning – Experienced teams schedule inspections and preventive maintenance to prolong system life.

Partnering with a skilled Underwater Lighting Installation Company in Kolkata ensures that installations are safe, efficient, and durable.

Also Read: Benefits of Professional LED Underwater Light Installation

Conclusion: Accessories Are the True Determinants of Underwater Lighting Success

Underwater lighting systems perform at their best when supported by high-quality accessories. Cables ensure safe power delivery, drivers regulate performance, and controllers provide precision and flexibility. Together, these components define reliability, safety, and longevity.

Rather than focusing only on fixtures, attention should be directed toward the elements that support them. With informed selection and expert planning, underwater lighting systems remain dependable for years.

For complex environments and region-specific challenges, professional guidance ensures that every accessory contributes to long-term success.

Frequently Asked Questions (FAQs)

1. Why do underwater lighting systems fail even when fixtures are reliable?

Underwater lighting failures usually stem from accessory-related issues rather than the fixtures themselves. Poor-quality cables, mismatched drivers, or improperly sealed junctions can lead to electrical faults, short circuits, or reduced system efficiency, compromising performance and longevity.

2. How are accessories selected for humid climates?

In humid regions, accessories are chosen based on IP (Ingress Protection) ratings, corrosion resistance, and insulation quality. High-quality cables, waterproof connectors, and sealed junction boxes ensure long-term reliability and prevent moisture-related failures, particularly in areas prone to heavy rainfall and humidity.

3. Are controllers necessary for basic underwater lighting?

Even for basic underwater lighting, controllers provide significant benefits. They allow precise control over brightness, timing, and color, reduce manual intervention, improve energy efficiency, and ensure consistent performance, making the system more adaptable and easier to maintain over time.

4. How often should underwater lighting accessories be inspected?

Regular inspection is critical to maintain performance and safety. Accessories should be visually checked at least once a year, with additional inspections after extreme weather events like monsoons, heavy rainfall, or water-level fluctuations to detect wear, corrosion, or insulation damage.

5. Can accessories be upgraded without replacing fixtures?

Yes, many underwater lighting accessories, such as drivers and controllers, can be upgraded independently. Upgrading these components improves system efficiency, adds automation or dimming features, and extends fixture life without requiring costly replacement of existing lighting fixtures.